Project Description

Dairy Technologies

Phone: 022 3922 091

Email: calvinwgreen@gmail.com

Website: www.dairytec.co.nz

Company: Dairy Technologies Ltd

Email: calvinwgreen@gmail.com

Website: www.dairytec.co.nz

Company: Dairy Technologies Ltd

Location Map

New Zealand Dairy Technology

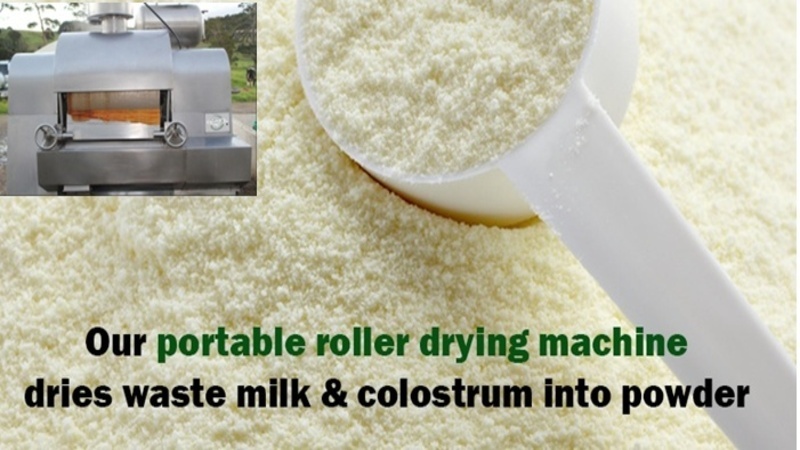

On Farm Milk & Colostrum Processing

Dairy Technologies has been the recipient of a grant from NZ Science and Technology for the development and improvement of the related technology. Over the past 12 months we have worked on our prototype and have made considerable changes to the design and effectiveness. We now have a Portable roller drum dryer capable of meeting market expectations.We have also developed a mini spray dryer the mini spray dryer is food grade and capable of processing colostrum – the highest value dairy product. We know that there will be high interest for this product, especially in Northland where colostrum is not collected. However, any dairy farm will have a use for this machine for producing dried colostrum for use in their calving program.

If you’re drying milk or colostrum on your farm for resale, you will need to weigh and pack it quickly and professionally. Dairy Tec’s weighing and packing machine has electronic load cell weighing and all stainless steel contact surfaces.