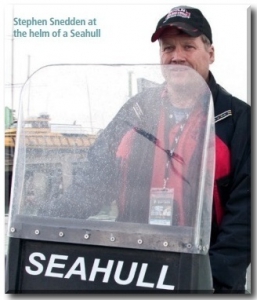

Stephen Snedden has been described as the inventor’s inventor and on meeting him it’s not hard to see why. He has an infectious enthusiasm, a can do attitude and a willingness to share his knowledge.

Stephen Snedden has been described as the inventor’s inventor and on meeting him it’s not hard to see why. He has an infectious enthusiasm, a can do attitude and a willingness to share his knowledge.

Stephen’s latest project is a 3.9 meter long, rotary moulded plastic catamaran with a 1.9 metre beam that he has designed and built the moulds for. But his story begins a long time before that. Brought up on a lifestyle block on the outskirts of Waiuku, Stephen got an early start in engineering, modifying and building mini-bikes and go-karts in his fathers’ shed. He started his career as an apprentice fitter and turner at the Glenbrook steel mill. While there, he won the 1989 National Youth Skills Olympics in Constructional Steel and went on to represent New Zealand at the International Youth Olympics in Birmingham England.

Inventor

To gain design and manufacturing experience he left Glenbrook and spent eight years working with an entrepreneur /inventor on a universal spanner project including helping him set up a manufacturing plant in Asia. Another project he helped developed was a range of trail able barges for marine farmers.

One in particular was a ten metre by 4.8 metre folding barge narrow enough when folded up to be towed behind a car. It could be un-folded and launched single handed and would support up to ten tonnes, the venture didn’t really fire despite their efforts. Stephen decided it was time to work for himself.

Catamaran

After starting his own welding business and working on the side building some conventional alloy barges, he began to develop a plan for a small fast catamaran. The boat was originally conceived in aluminium but Stephen decided that moulded plastic was the way to go. It had many advantages over alloy or fiberglass. He drew up his design and started planning the moulds. While his wife was away on an overseas holiday Stephen threw every waking hour into the project and working from little more than a sketch had the moulds finished by the time she returned. That was no mean feat. The hulls are a series of complex, folded and stitched sections running up to compound curves in the bow. Each panel was folded and every seam had to be stitched, welded, faired and panel – beaten smooth. He had a few hulls moulded and learnt from mistakes as he did so. Named Seahull, the boats have been shown at Fieldays, at last year’s Auckland Boat show and Big Boy’s Toys. The response has been great with lots of interest and several hulls sold. One has even been converted to electric propulsion. Not content to rest with the basic model, he is busy building moulds for front, rear and centre helm stations, and an integrated chilly bin. A cuddy cabin design is also on the drawing board.

Abridged article from The Shed May 2013 written by Roger Lacey

Leave A Comment

You must be logged in to post a comment.